Polymer-Plastic Technology

Polymer-Plastic Technology and Engineering

Polymers are large molecules that are composed of a combination of small molecules called monomers. They have a wide range of properties and play an essential role in our everyday lives. Polymers are generally of two main types – Synthetic and Natural.

Plastic is also a polymer. Plastic consists of a wide range of synthetic and semi-synthetic organic compounds that are malleable in nature. Plastics are commonly derived from petrochemicals and are made from renewable materials including cellulosic and polylactic acid which comes from cotton liners and corn respectively. Plastics are specially engineered to hold some specific properties out of which plasticity is the general property which allows the plastic to irreversibly deform without breaking.

Plastic is also a polymer. Plastic consists of a wide range of synthetic and semi-synthetic organic compounds that are malleable in nature. Plastics are commonly derived from petrochemicals and are made from renewable materials including cellulosic and polylactic acid which comes from cotton liners and corn respectively. Plastics are specially engineered to hold some specific properties out of which plasticity is the general property which allows the plastic to irreversibly deform without breaking.

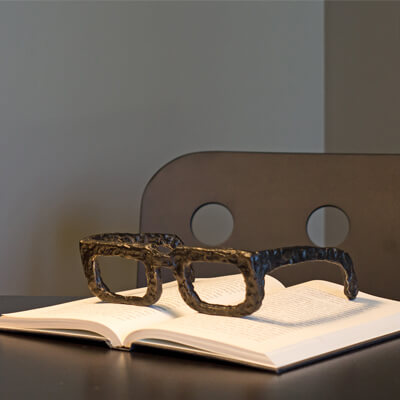

The plastic technology is developed to make materials which are highly malleable and can be molded to any shape and form without being destroyed. This technology is being used to design, develop and manufacture products made of plastic which is used by us daily.

Plastics are in semi-liquid state and have the property to exhibit flow and plasticity. Plastics engineering involves plastics material and plastic machinery. All types of machinery and equipment that are used in the plastics processing industry are generally known as plastic machinery. Plastic materials are specially made and it is the job of the Plastics engineer to design a product which will exhibit certain specifications at a low cost. Many properties need to be incorporated in the material including resistance to chemical attack, extreme temperatures, pressures and weather conditions.

Like most engineering disciplines, the financial side of a product plays a significant role in plastics engineering. The price of plastic materials varies from the cheapest material which is used in making mass-produced everyday products to specially made expensive materials used for specific purposes only. The value of a plastic product is estimated in diverse ways, and the total price of a plastic material is hard to determine. Cost is often calculated in price per pound or price per unit volume of the plastic material. In numerous cases, though, it is essential for a product to meet certain conditions, and cost could then be calculated in price per unit of a property it exhibits. Price with respect to processability is often significant, as some materials need to be treated at very high temperatures, increasing the quantity of cooling period a part requires.